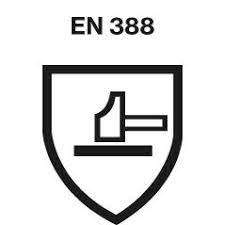

When it comes to protecting your hands from dangerous environmental hazards, EN 388:2016+A1:2018 is the standard to trust. Protective gloves are essential when working with sharp objects.

What is EN 388:2016+A1:2018 mean?

EN 388:2016 + A1:2018 is a European standard that outlines the requirements for protective gloves used in mechanical and physical work. The standard is designed to ensure that gloves provide effective protection against mechanical risks, such as abrasion, cut, tear, and puncture.

EN 388:2016+A1:2018 is the most recent version of the European safety standard for protective gloves against mechanical risks. The standard is a major update to the EN 388:2003 edition and was published as an amendment to EN 388:2016 in December 2018.

Safety gloves testing method according to EN 388:2016

Abrasion is a type of damage that occurs when a material is rubbed or scraped against a rough surface. This type of damage is often seen on surfaces that are frequently exposed to friction, such as on the soles of shoes or on the surface of a road. Abrasion can cause materials to become worn down and lose their original texture or shape.

A cut is a type of damage that occurs when a sharp object such as a knife or scissors cuts through a material. This type of damage is often seen on fabrics, paper, and other thin materials. A cut can cause a material to become separated or divided into two or more pieces.

A tear is a type of damage that occurs when a material is pulled apart or stretched beyond its limit. This type of damage is often seen on fabrics, paper, and other thin materials. A tear can cause a material to become frayed or have a hole in it.

A puncture is a type of damage that occurs when a sharp object such as a nail or needle pierces through a material. This type of damage is often seen on rubber, leather, and other flexible materials. A puncture can cause a material to become ripped or torn around the area where it was punctured.

EN 388:2016 + A1: 2018 – markings explained

The standard specifies a range of tests that gloves must undergo to assess their resistance to these risks. These tests include abrasion resistance, blade cut resistance, tear resistance, and puncture resistance. Gloves are then given a performance rating based on their results, with a scale of 1 to 4 for each test.

| Example code under pictogram | Performance levels | What the test is for |

|---|---|---|

| 3 | 1-4 | Abrasion resistance |

| 4 | 1-5 | Cut resistance (Coupe Test) |

| 4 | 1-4 | Tear resistance |

| 3 | 1-4 | Puncture resistance |

| E | A-F | Cut resistance (EN ISO 13997) |

| P | P | Impact protection (EN 13594) |

In addition to the mechanical risks, EN 388:2016 + A1:2018 also addresses other factors that may be relevant to protective gloves. These include glove design, sizing, comfort, and durability. The standard also specifies requirements for labeling and packaging of gloves, as well as instructions for use and maintenance.

Conclusion

EN 388:2016 + A1: 2018 is an important standard for protective gloves and provides a comprehensive evaluation criterion to ensure the safety of workers and consumers in a wide range of workplace environments. It is a comprehensive and well-rounded standard that is designed to protect those who use it from potential harm and injury. As such, it is important for businesses and individuals to be aware of and adhere to this standard when purchasing or using protective gloves.

Looking for a high quality supplier of CE gloves in Pakistan and specialize in the production, export of a wide range of CE gloves and Well reputated for producing high quality products.

If you are wondering to know Why Pak Benelux Safety Wears is a Top Manufacturer of Gloves in Pakistan, check out our post here!